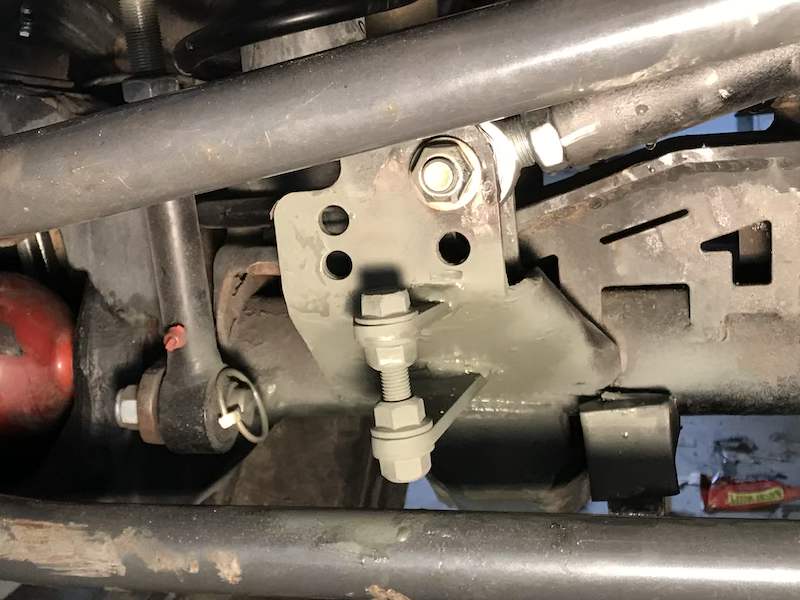

Andy used his CNC plasma to cut out a couple tabs that I welded onto my track bar mount for the steering stabilizer. The welds aren’t pretty, but it’s not going anywhere. It was nearly impossible to get the MIG gun in between the two tabs without taking the axle out of the Jeep. Now the shock is up and out of the way, and horizontal.

A few more things to button up

Got a lot done on the Jeep. Suspension is almost all wrapped up.

I still need to get the steering stabilize remounted. I hated the old mount. I took some measurements to build a custom mount that I will weld onto the track bar mount.

Teraflex big rotor kit is done. These rotors are beefy. I should be able to hold the Jeep on an incline and not feel like I have to put all my weight on the brake pedal.

When I was torquing all the bolts, I notices the passenger lower shock mount skid was worn almost all the way through. Wow. This started out as 3/16″ steel. I guess I drag my ass just a little too much. LOL! A little weld and some grinding it smooth took care of that. I might come back later and add an additional piece of plate steel to the bottom of this skid.

Continuing the rebuild

Easter Jeep Safari is right around the corner, so I need to get the Jeep finished. I’ve been spending so much time on the workshop over the winter, that the Jeep has been neglected a bit.

But now that I have the workshop, I have a lot more space to work. I moved my parts rack into the shop and used it to set the jam nuts.

I built this extension for the wrench to tighten the jam nuts. With this much leverage, I don’t think getting to 300 ft. lbs. of torque is going to be an issue. I have no way of knowing just how much torque I am putting on them, but I guarantee it’s enough.

Torque jig

When I put the control arms back together, one of the most important things is to make sure that the jam nuts on the flex joints are torqued down VERY well. Rock Krawler specifies 300 ft.lbs. of torque. This is needed in order to keep the jam not from backing off. Once it does the threads will start to wear and eventually the joint will just pop out of the control arm.

I built this jog from some 1/4″ steel. It’ll keep the one end clamped to the workbench. The other end is slipped into another jig into a vice, keep then flex joint properly oriented. I’ll then be able to get the wrench on the jam nut and crank on it. Should do the trick.

Clearing threads

Once the control arms were back from the powder coater, and before I started reassembly, I wanted to make sure the internal threads were clear. I would imagine there was some surface rust at least in there.

I didn’t have a tap that big, and no way I was going to spend that kind of money, so I diced to make my own thread clearing tool from the old control arm ends. I ground some slots into a decent example of each size, used the torch to heat it up for a heat treat to harden it, and then was able to use it to clear all the internal threads. Worked like a charm.

DIY Bushing

When I removed one of the the rear shocks, I have to cut the bolt off with a torch. The bolt had rusted the lower bushing and would not come out. This destroyed the rubber bushing.

Unfortunately, it’s not available from the manufacturer. I found a set of bushings from Daystar, but the internal sleeve size was different than the stock bolt. It was too big.

I had recently been given the opportunity to be trained on the lathe at the CWRU thikbox, so I decided to make a bushing as my first real project!

Problem solved.

Much better!

Dropped all the parts to be powder coated off at 440 Powder Coating and a couple weeks later, I got them back. Everything came out great.

Had the control arms done in black. And he did the wheel rims in Cleveland Indians blue. They were so beat up and bent, it was time for some fresh color.

Suspension Deconstruction

I spent some time over the last couple weeks getting the rest of the suspension removed from the Jeep. Some of those bolts were too tight to get off. But, as they say, it’s ain’t tight if it’s liquid! I had to use the torch to CUT the bolts off in a couple places. There’s just no way it was coming apart. The bolt itself had seized into the heim joint of the suspension. Burning it out was the only choice.

Removing the joints from the suspension arms proved to be another challenge. Some heat and penetrating oil did the trick. I mounted a vice to the storage rack I built this year and it gave me a nice strong platform to get some big wrenches on the jam nuts and such.

Rebuild Progress

I’ve been making some progress getting things apart. Got the wheels off and the Jeep on jack stands. I bought a couple pair of 12 ton jack stands from Harbor Freight to get the Jeep up in the air as high as possible without hitting the garage door or opener.

I also removed the engine skid. It is bent pretty bad. I must have hit that on some rocks a few too many times. But I have a solution for that. Stay tuned!

Time to start the rebuild

My wheeling trips are done for the year. I need to get started on the rebuild of the suspension. I’m already replacing all the control arm ends and springs. There are a few other things I want to do as well. But I need to remove the suspension completely from the Jeep. The control arms, track bars and drag link are all going to get media blasted and powder coated.

Time to get this started. The oxy-acetylene torch is already coming in handy. Some of these bolts are super rusted and need a little persuasion with some heat.