I set up an old video camera on a tripod, put a welding shield in front of it, and was able to film this arc shot of a TIG weld. If the sensor in the camera had a better dynamic range, I think I would have been able to capture some more detail in the arc.

Homemade Harrow

We had this 90′ maple tree removed from our backyard. I was sad to see the tree go, but a good part of the trunk was rotten and spongy. After the stump was ground and the mess cleaned up, I wanted to fill the hole with some top soil and plant some grass. Moving around 7 yards of dirt was going to be a chore, so I made my version of a harrow that I could pull behind my lawn mower.

I used my PrimeWeld TIG 225 in stick welding mode mostly because I wanted to practice SMAW and also because I didn’t want to spend a lot of time cleaning the metal.

I think it came out great, especially since this was all from scrap metal I had lying around the shop. It did exactly what I needed it to do and made the job a lot easier. I made this YouTube video of the build and part of how I was able to use it.

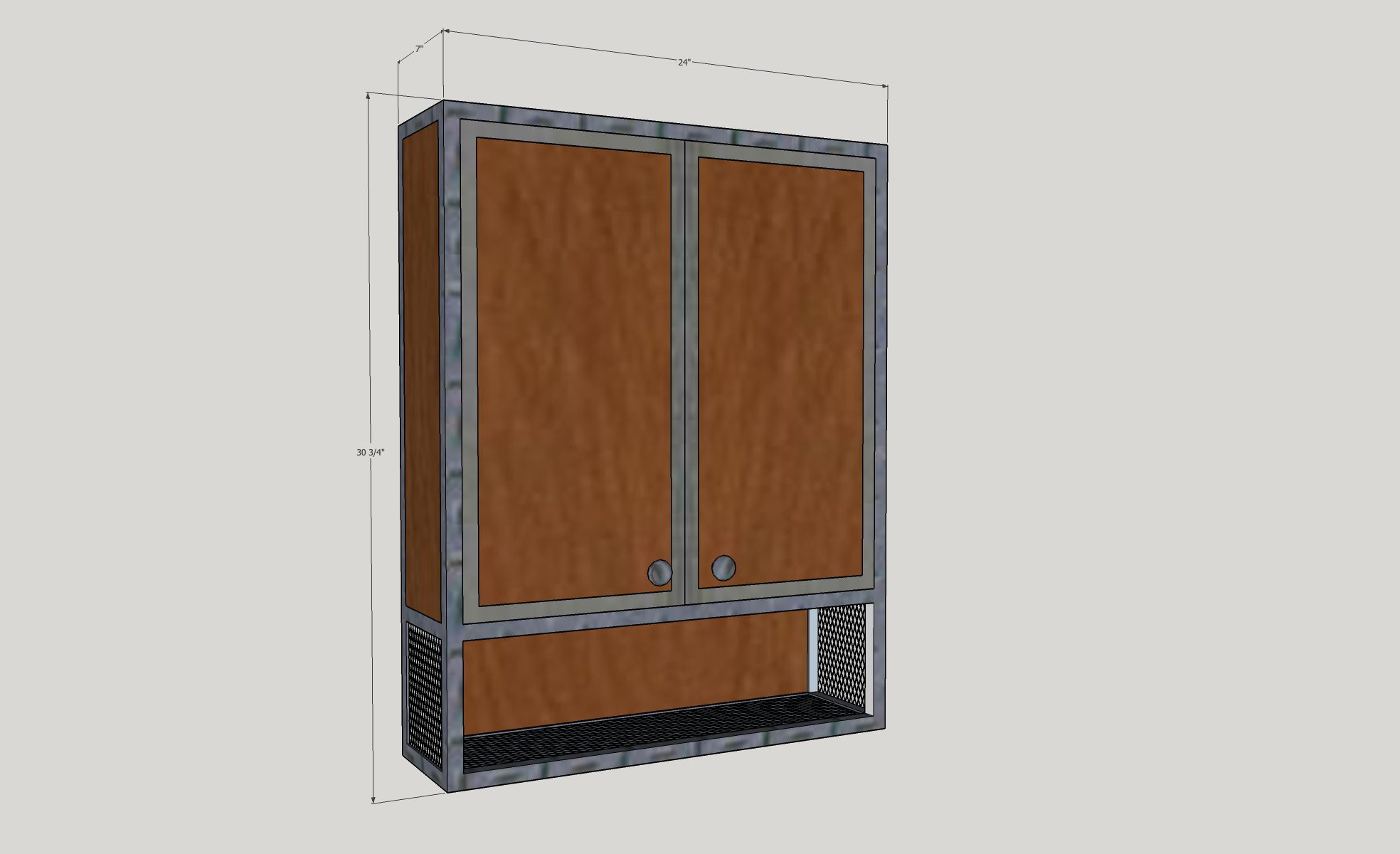

Bathroom Cabinet Project – Part 1

One of the projects I have been wanting to build for a couple years now is a new wall cabinet for our downstairs half bath. This room is very small, barely enough to fit a toilet and an extra small sink. There’s no storage at all. I thought about just buying a cabinet to go over the toilet, but I wanted to make something. Something from steel and old wood. I designed it in SketchUp.

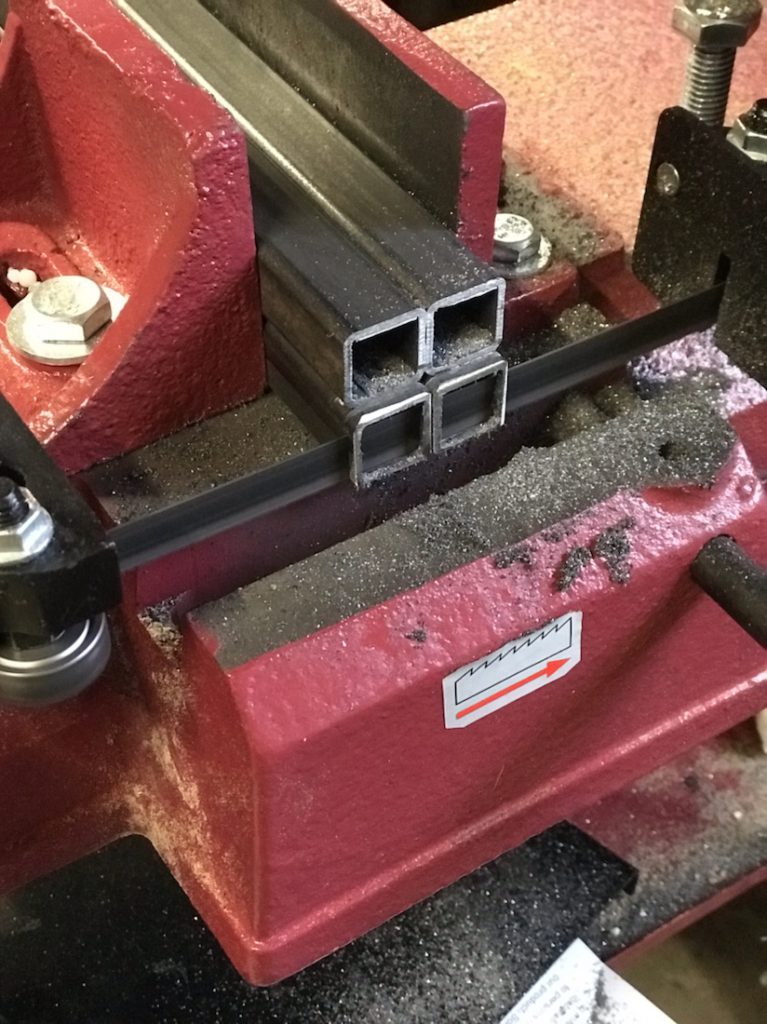

I had the steel lying around for a while, I bought it before the workshop even existed. I put the Harbor Freight bandsaw to use cutting each of the pieces of angle and square tube.

For a cheap saw, I have it dialed in to cut very straight and accurate. I needed quite a few small pieces, needed to do a little bit of grinding to get the lengths just right.

I still need practice with the TIG welder, so I decided to use this project. Tacked everything together before finish welding with the TIG 225X.

Having the welding table and my homemade clamps made this a lot easier. I also used a set of Hobart corner clamps to get me started.

One of these days I will have to invest in some Fireball Tools squares, but they are very expensive. I might try designing a set and cutting them out on the water jet at CWRU.

I need to go get the rustic wood for the cabinet, and make the doors yet, and the figure out what I want to do for a patina. But with the Coronavirus lock down, I can’t really go anywhere.

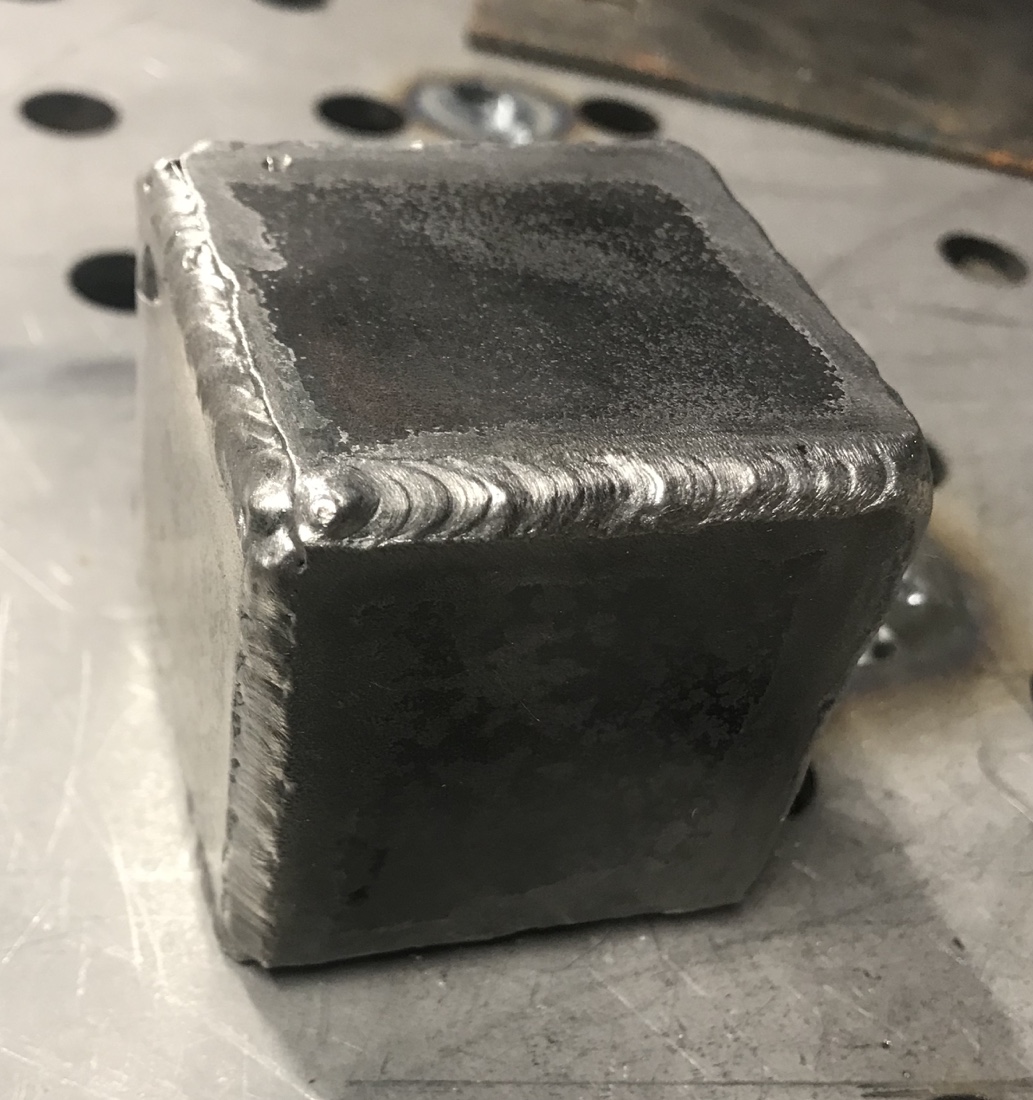

Welding a 2″ Cube

I wanted to get a little TIG practice in with the Primeweld TIG 225X. I had some 2″ mild steel flat bar left over from a different project, so I decided to cut it up into roughly 2″ lengths and weld it together to make a cube.

My welds still need a lot of work, but every bit of practice counts. I should have taken my time on this, but, TBH, I was just happy to be welding.