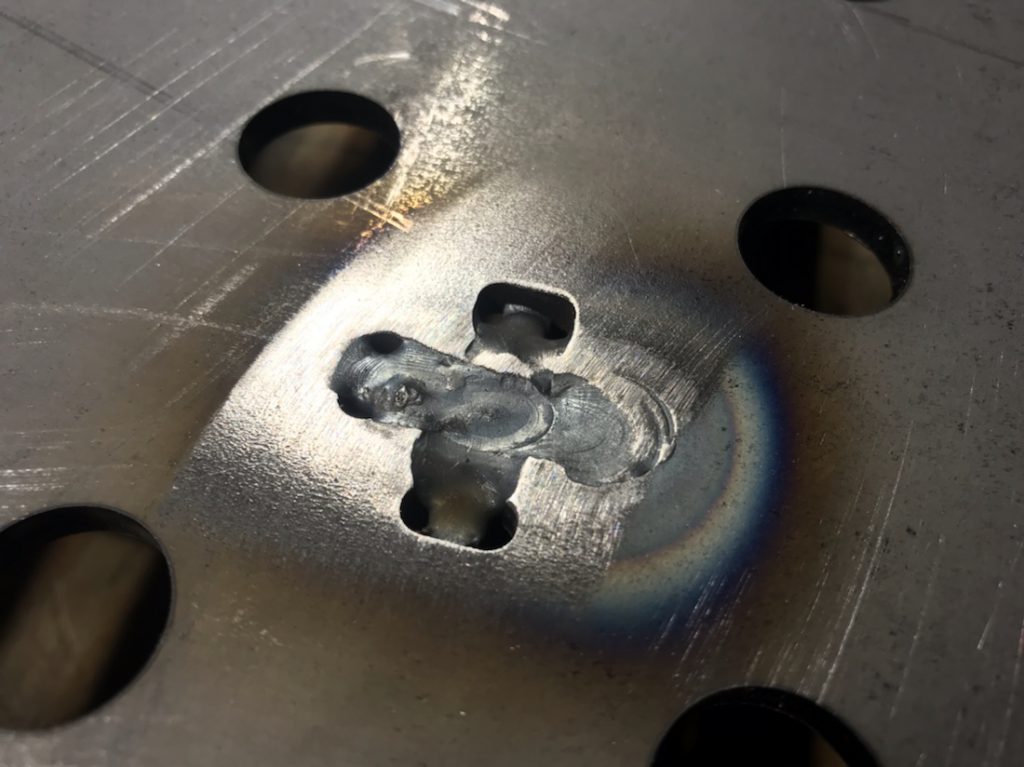

Practicing on some 1/16” aluminum coupons from @weld_metals_online before I try the real fix.

.

.

.

Need a tool. Make a tool.

If only I knew someone that could TIG weld aluminum.

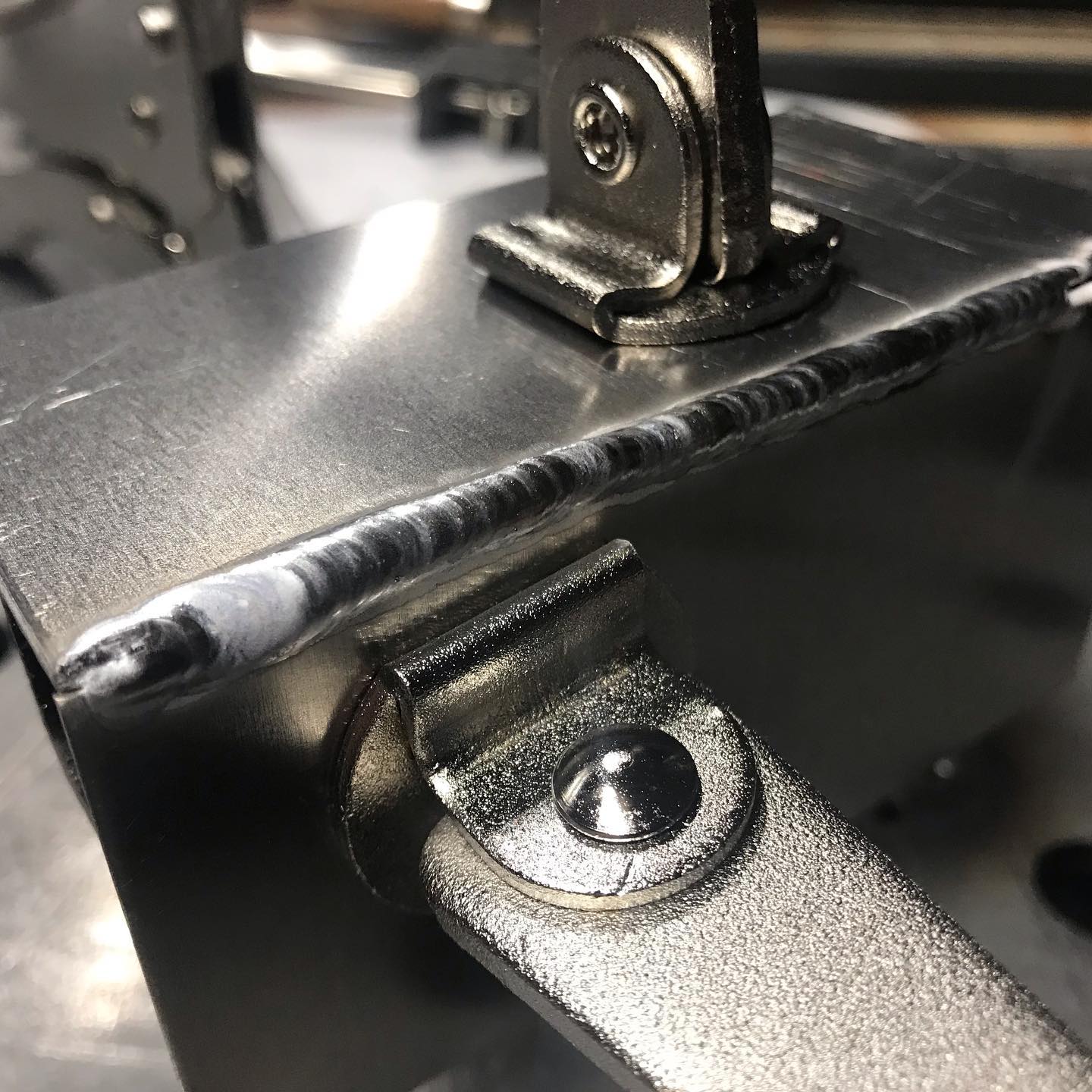

Stacking dimes!

Stacking dimes! Welding nuts on the inserts that will be welded to the bottom of the legs of the welding table. .

.

.

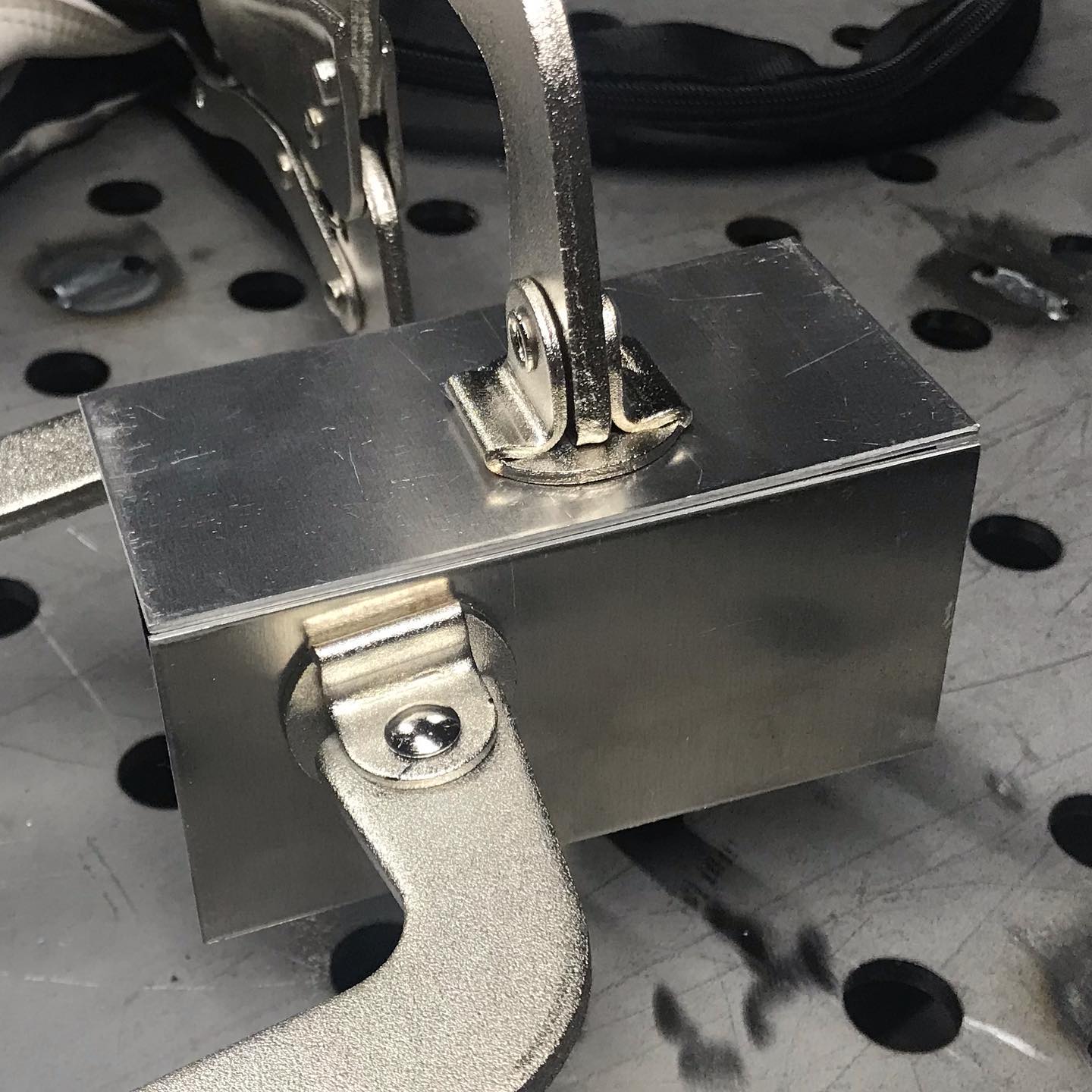

Made some hold down clamps out of some 5/8” round bar and a few old HF clamps.

Made some hold down clamps out of some 5/8” round bar and a few old HF clamps. .

.

.

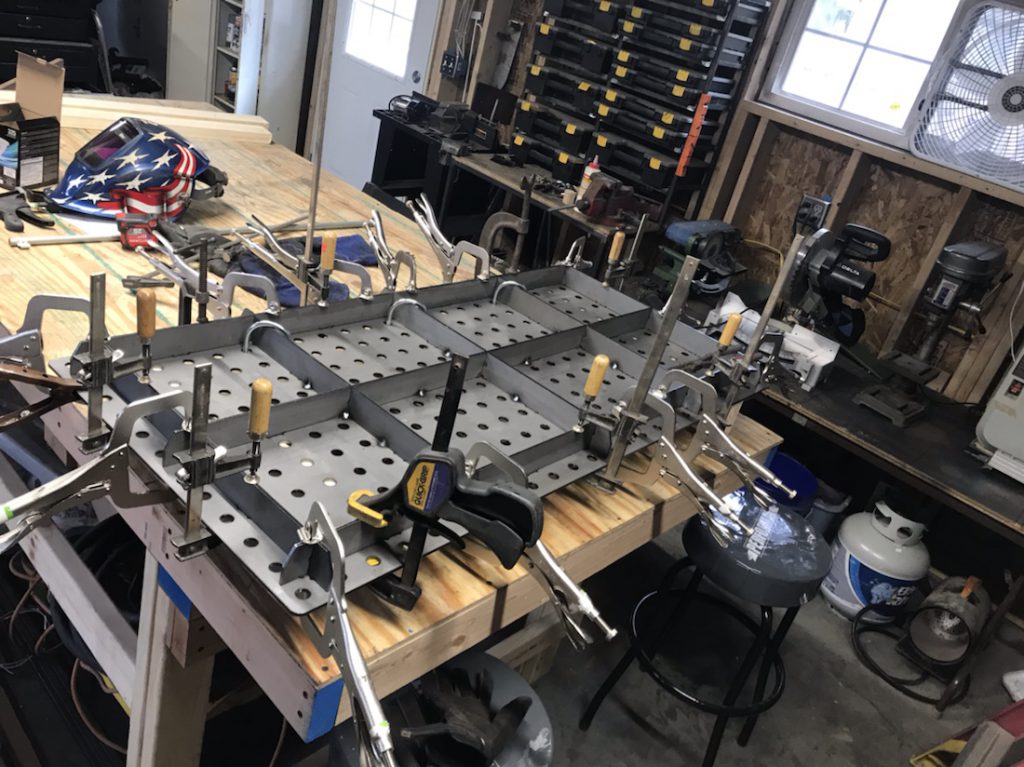

The welding table top is all welded together.

The welding table top is all welded together. Took my time making sure everything was clamped down and flat. You can never have too many clamps. 😉

.

.

.

New welding table (almost)

I have been wanting a welding table from Certiflat for YEARS. I can’t remember just where I first saw them. I finally had the space and the budget to get one this year.

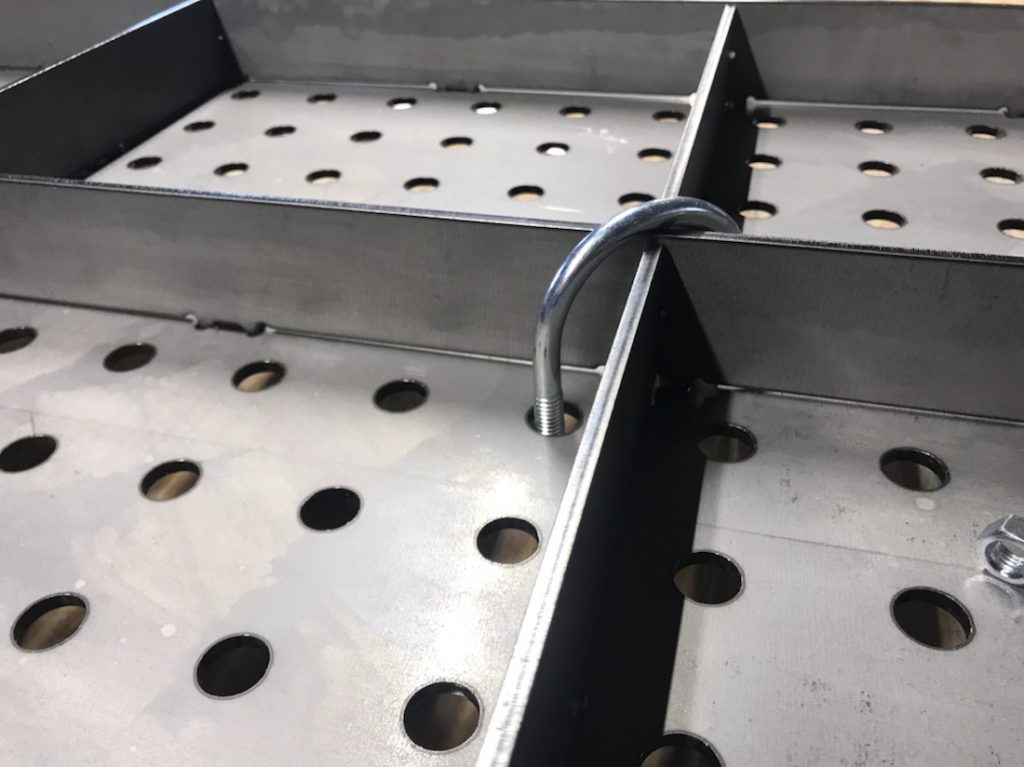

It comes in pieces. A flat top, laser drilled with 5/8″ holes every 2″. There are also slots cut into the top where the tabs on the support ribs fit into.

You start the build upside down, clamping the ribs to the top piece. You have to clamp it down completely to ensure the top comes out flat.

I used u-bolts to clamp down the center pieces.

I used the MIG to tack weld the center parts of the ribs together and to the table top. and then added more clamps to the outsides of the ribs.

A lot of clamps. You can never have too many. I used a flashlight to make sure there was no space between the ribs and the top, shining it on the side opposite to where I was standing, making sure I saw no slivers of light come under neath the rid.

Once it was completely tacked together, I turned it over and used the TIG welder to complete the welds of the tabs and slots.

My TIG welding still needs practice, but that’s part of what this table is for. I’m debating on if I will finish welding the ribs below. I don’t think it really needs it.

The legs I ordered with this table haven’t been shipped yet. Once those are in, I’ll be able to complete this project.

UPDATE: Leg kit arrived.

I have been wanting one of these for years!

I have been wanting one of these for years! Can’t wait to build it and start putting it to use. .

.

.

Starting to get more done to the shop again.

Starting to get more done to the shop again. Ran a couple 220v circuits for each of the welders plus a 110v circuit for some much needed outlets. Changed my plans a bit and swapped the welders to the east wall so the runs are shorter.

.

.

.

Decided to raise the workbench up to a total of 40”

Decided to raise the workbench up to a total of 40”. Seemed like it was going to be tall, but I really like it. It’ll match up well with the soon to be ordered @weldtables welding table.

.

.

.