I think I have finally figured out the porosity issues I am having with my @hobartwelders 175 MIG welder when using ER70S-6 solid wire and C25 gas. That aluminum block in the second photo is the gun connector. It and the brass fitting on the gun, third and forth, had corroded so badly that I am sure there is an air leak. Trouble is, that part is no longer available. So until the Bridgeport is up and running so I can make a new one, going to have to resort to E71T-11 flux core. It welds nice, but the smoke and fumes is a pain when welding indoors.

.

.

.

.

A while back, the Mule’s chariot needed modified.

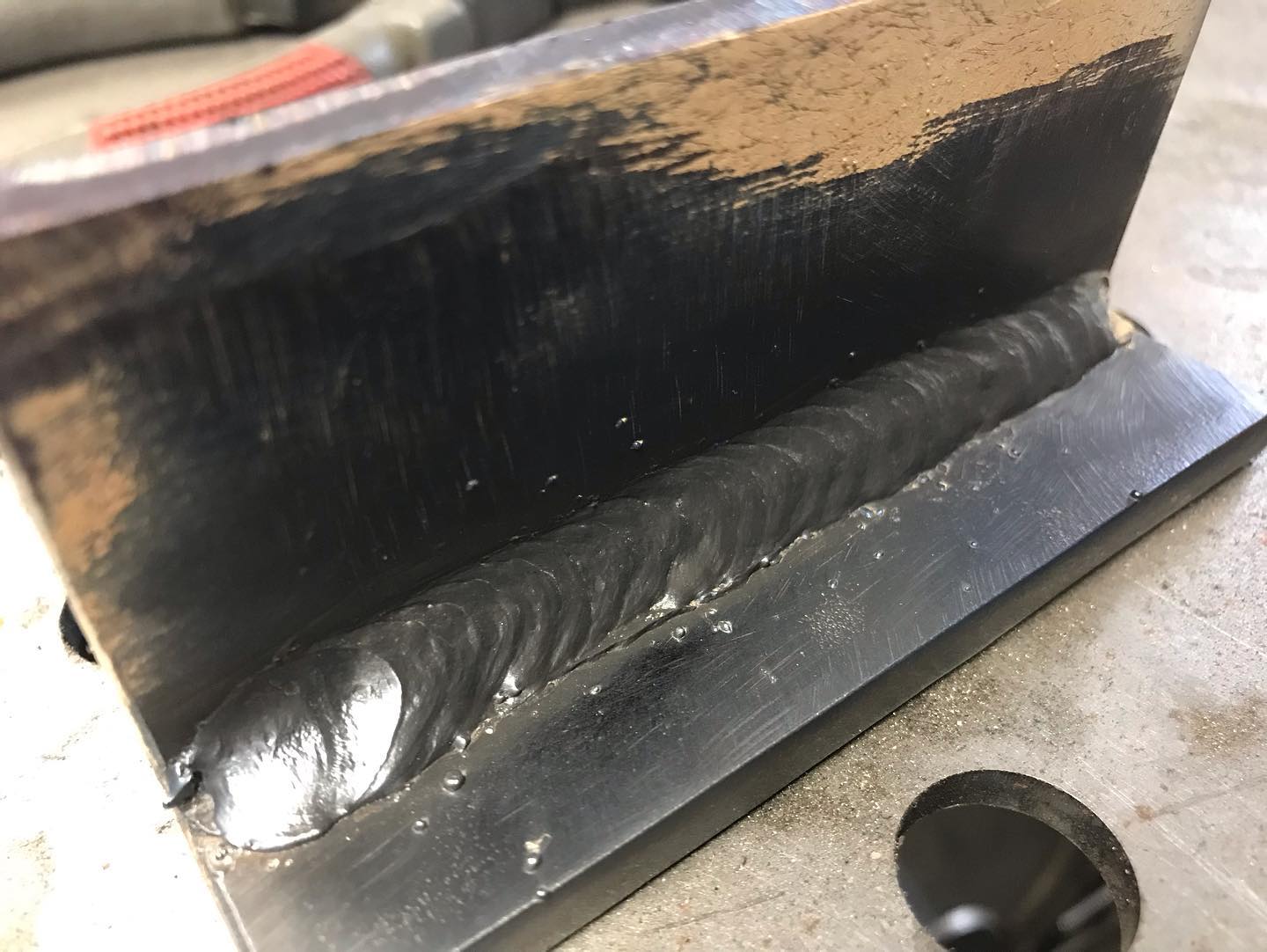

A while back, the Mule’s chariot needed modified. I bought a weight distribution hitch and the tool box that was welded to the tongue was in the way. A little grinding and a few stitches 😬later, and it was off. Welded it back on today with some spacers to clear the hitch brackets. First time using flux core wire – since I was outside and figured the gas would not be as reliable. Welds a lot different than solid wire. Not my best work, but it’s not going anywhere. .

.

.

.

.