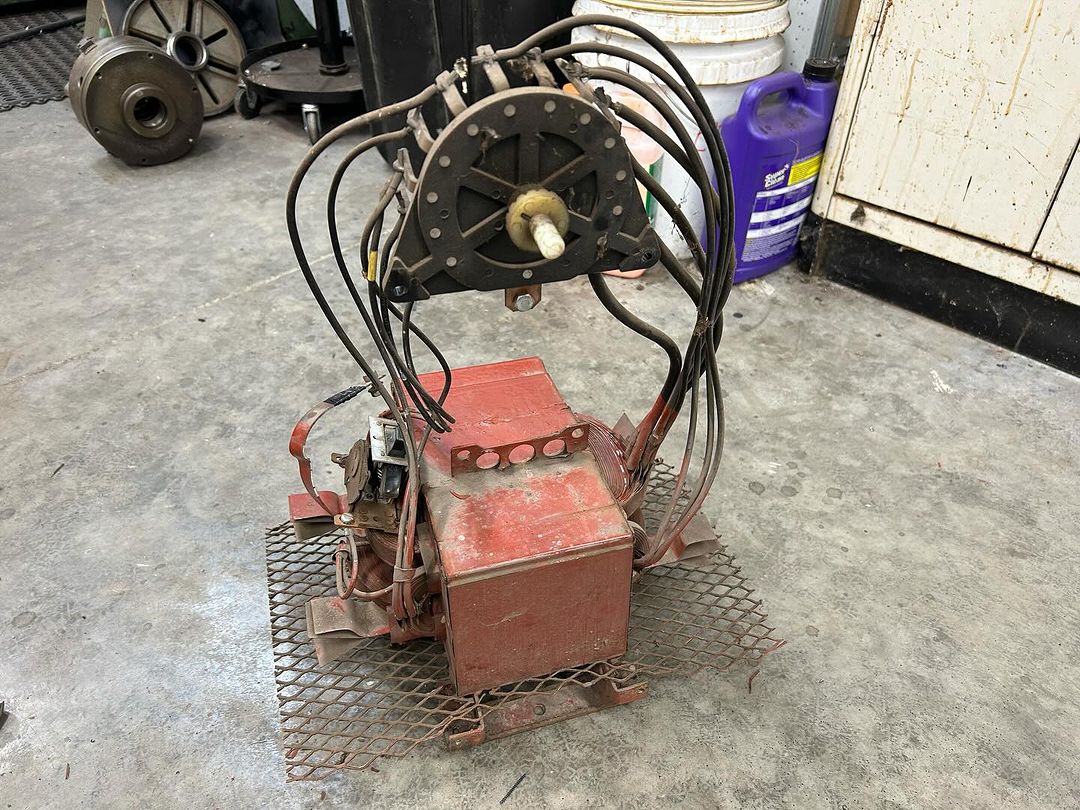

This is what your welder looks like when it’s naked.

I made a second version of a welding square.

I made a second version of a welding square. These were drawn up in Fusion 360, exported as DXF files, and then sent to a CNC water jet controller and cut from .250 steel.

•

•

•

•

•

Don’t tell the cops!

Don’t tell the cops! ;)

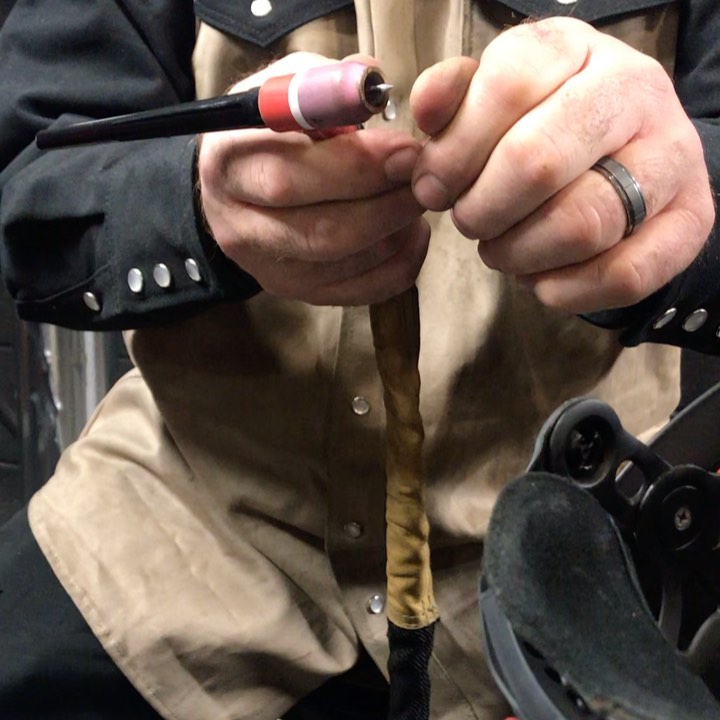

I was making some tack welds on a project the other day and it was awkward to reach some of the areas with the torch and reach the foot pedal at the same time. I installed the finger trigger on my TIG torch to make these operations easier. I made a video of the results and some explanation of what how some of the controls on the welding machine are affected.

•

•

•

•

•

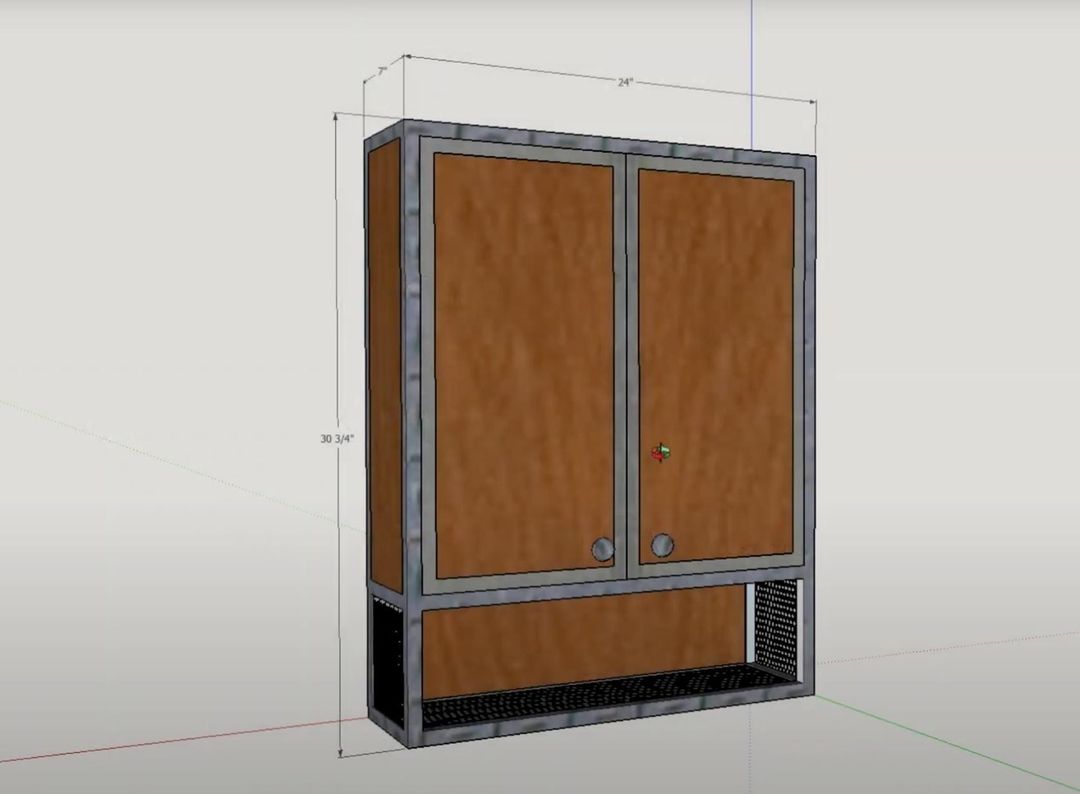

I had designed this small cabinet a while ago.

I had designed this small cabinet a while ago. When I find time, I try and make progress on it. I have the main frame finished, not it’s time to add some doors.

I saved hundreds of dollars by using my Primeweld TIG 225

I saved hundreds of dollars by using my @primeweld TIG 225 to make these locking clamps for my @weldtables welding table.

Getting all the TIG and other welding stuff organized.

Getting all the TIG and other welding stuff organized. Bought this tool cart used and cleaned it up. Now I just need to get better at using all this stuff.

.

.

.

.

Completed a week long class in TIG (GTAW) at Lincoln Electric Welding School.

Completed a week long class in TIG (GTAW) at Lincoln Electric Welding School. Hats off to our instructors, Lance and Karl. They’re tops! I appreciated the attention you can only get one on one. Unexpectedly, we also learned a lot about metallurgy. Nice bonus! Lots of time under the hood. Still need lots of practice. Hoping to score some scrap metal from some local scrap yards and still need to get a lot more filler rod. Might have to find some more classes to take!

.

.

.

.

High Frequency Start explained.

I’m starting to get there. Need lots more practice.

I’m starting to get there. Need lots more practice. Thanks @coonasswelder for the instruction!

.

.

.

.