Once you get a 3D printer, it’s interesting to see all the stuff you can make that you never thought about. I made this threaded spindle protector for the lathe. At least while it’s being restored. These threads are crucial and any damage to them would be very costly to repair.

.

.

.

.

.

.

.

I removed the apron on the South Bend 13″ lathe.

I removed the apron on the South Bend 13″ lathe. Ooof. I though the chuck was bad. This is the worst. The video for this may take a while, because recording it is going to take a while.

.

.

.

.

.

.

.

Very happy with how this chuck for my 1941 South Bend 13″ lathe cleaned up.

Very happy with how this chuck for my 1941 South Bend 13″ lathe cleaned up. Small steps. So much more to do in order to get the lathe running again. Sorry, still not a Jeep picture – it’s winter – the Mule is hibernating. ;)

.

.

.

.

.

.

.

Cleaning the gunk out of this 3 jaw chuck for my 1941 South Bend 13″ lathe.

Cleaning the gunk out of this 3 jaw chuck for my 1941 South Bend 13″ lathe is going to take a while. Thank goodness for @evap_orust and Purple Power degreaser.

.

.

.

.

.

.

.

Since my 1941 South Bend 13″ lathe doesn’t have any digital readout

Since my 1941 South Bend 13″ lathe doesn’t have any digital readout (nor will it ever), you have to rely on indicators like this to know how much material you have cut off, or where to stop. I needed a way to hold it on the lathe accurately. So I designed this part in Fusion 360 and 3D printed it. Along with about $4 in hardware, I can clamp a dial indicator to the bed way, and the carriage will come in contact with the plunger on a machined face. Should work out very well for me.

.

.

.

.

.

.

.

Opening up the 3 jaw chuck on the South Bend Lathe and this is what I find.

Opening up the 3 jaw chuck on the South Bend Lathe and this is what I find. Globs and globs of gunky, greasy, swarf (little tiny flakes of metal). It looks like mud.

.

.

.

.

.

.

.

I’ll take the 4×4’s off at some point.

I’ll take the 4×4’s off at some point. But I’ll be starting from the top and working my way down. Disassembling and cleaning as I go.

.

.

.

.

.

.

.

Not as sketchy as it looks.

Not as sketchy as it looks. Used the hoist to lower this thing to the ground. 1500 pounds.

.

.

.

.

.

.

.

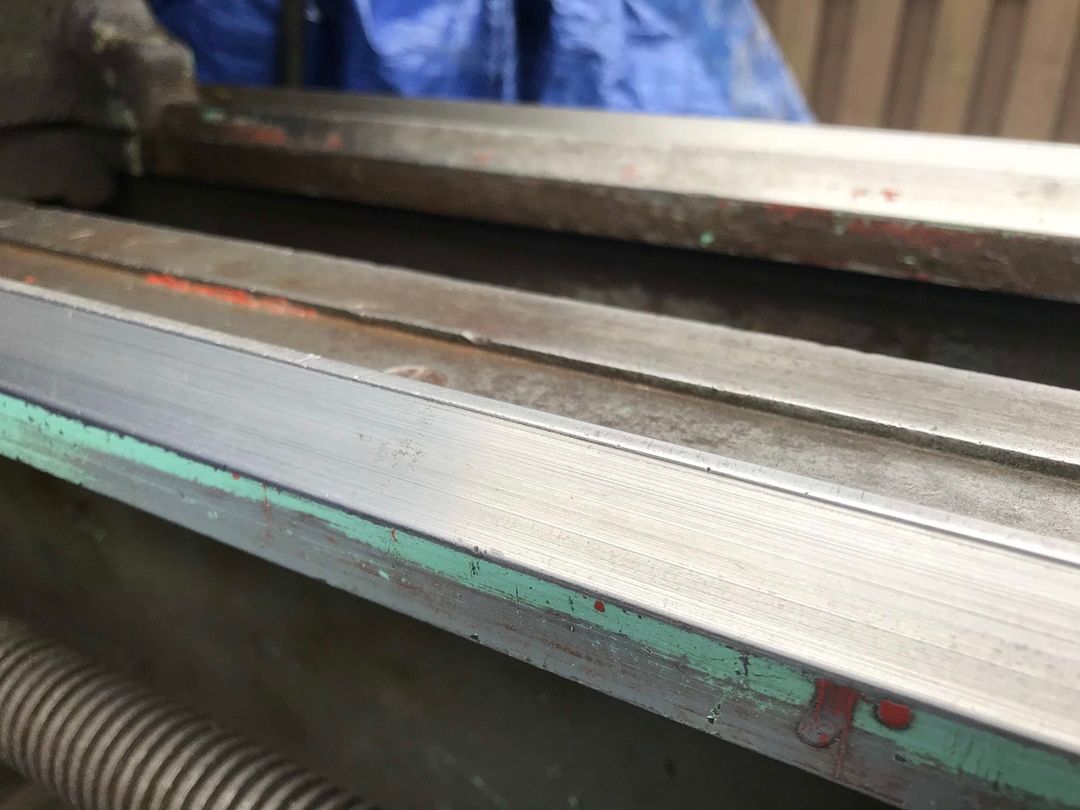

The bedways on the 1941 South Bend 13″ are a bit worn.

The bedways on the 1941 South Bend 13″ are a bit worn. Probably not bad enough to make it unusable. If I find they are that bad, I might look into having them planed and scraped. That’ll cost a lot, but I didn’t pay that much for the lathe and would make is usable for decades.

.

.

.

.

.

.

.

This lathe was built in 1941.

This lathe was built in 1941. And surprisingly, it shows it. 😉

.

.

.

.

.

.

.