I disassembled the cross slide on my 80 year old metal working lathe. Lots of little pieces, and some that were just plain wrong.

.

.

.

.

.

.

.

Sneak peek of how the reversing lever is turning out.

Sneak peek of how the reversing lever is turning out. I’m dropping a video on YT this Friday of the teardown of the main gear train on my 80 year old lathe.

.

.

.

.

.

.

.

Picked up this 80 year old copy of the Machinery’s Handbook.

Picked up this 80 year old copy of the Machinery’s Handbook. This has charts, data, and specifications on just about anything you would need to make on a lathe or other machines. Things like how deep the threads for a 1-7/8″-8 spindle would be. A must have for any budding machinist. And I specifically wanted an edition as old as my lathe, for nostalgia more than anything.

.

.

.

.

.

.

.

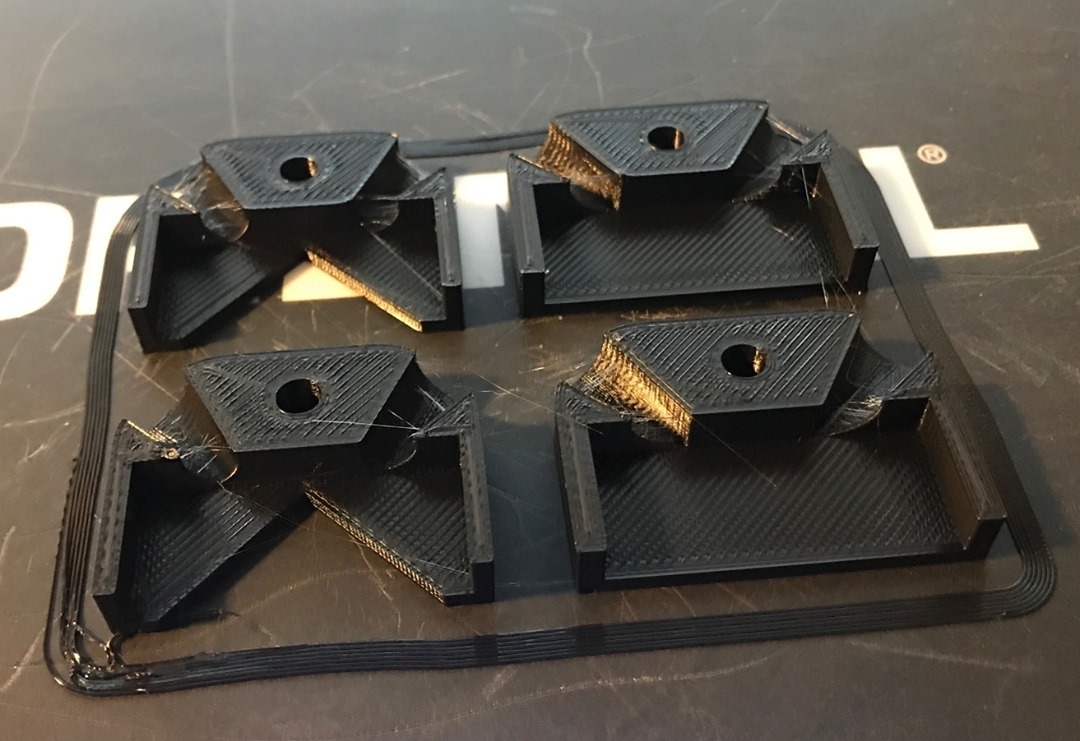

You never realize how useful a 3D printer can be until you have a 3D printer.

You never realize how useful a 3D printer can be until you have a 3D printer. The tailstock for my 1941 South Bend lathe did not have way wipers on it. The way wiper clears away junk on the ways (where the tailstock slides) preventing that junk from getting under it and damaging the ways. So I drew up and made a set of way wiper covers that I will mount on the tailstock with machine screws. I even incorporated some oil passageways to occasionally add more way oil.

.

.

.

.

.

.

.

Once you get a 3D printer, it’s interesting to see all the stuff you can make.

Once you get a 3D printer, it’s interesting to see all the stuff you can make that you never thought about. I made this threaded spindle protector for the lathe. At least while it’s being restored. These threads are crucial and any damage to them would be very costly to repair.

.

.

.

.

.

.

.

I removed the apron on the South Bend 13″ lathe.

I removed the apron on the South Bend 13″ lathe. Ooof. I though the chuck was bad. This is the worst. The video for this may take a while, because recording it is going to take a while.

.

.

.

.

.

.

.

A little before and after of the catalog plate on the 1941 South Bend lathe.

A little before and after of the catalog plate on the 1941 South Bend lathe. After cleaning the brass, I painted it with red enamel paint. Then painstakingly scraped all the letters.

.

.

.

.

Very happy with how this chuck for my 1941 South Bend 13″ lathe cleaned up.

Very happy with how this chuck for my 1941 South Bend 13″ lathe cleaned up. Small steps. So much more to do in order to get the lathe running again. Sorry, still not a Jeep picture – it’s winter – the Mule is hibernating. ;)

.

.

.

.

.

.

.

Cleaning the gunk out of this 3 jaw chuck for my 1941 South Bend 13″ lathe.

Cleaning the gunk out of this 3 jaw chuck for my 1941 South Bend 13″ lathe is going to take a while. Thank goodness for @evap_orust and Purple Power degreaser.

.

.

.

.

.

.

.

Since my 1941 South Bend 13″ lathe doesn’t have any digital readout

Since my 1941 South Bend 13″ lathe doesn’t have any digital readout (nor will it ever), you have to rely on indicators like this to know how much material you have cut off, or where to stop. I needed a way to hold it on the lathe accurately. So I designed this part in Fusion 360 and 3D printed it. Along with about $4 in hardware, I can clamp a dial indicator to the bed way, and the carriage will come in contact with the plunger on a machined face. Should work out very well for me.

.

.

.

.

.

.

.