When I assembled the compound of my lathe, I noticed a lot of slack in the screw, .025″ or more. I make an attempt and fixing that, but first facing off the dial and the bushing to remove the wear marks, and then by making an aluminum washer to take up the slack. I got most of it out, but not as much as I would have liked. Link my bio.

.

.

.

.

.

.

.

BEFORE

Machining some mystery metal for a project.

Machining some mystery metal for a project. Still learning proper speeds and feeds on the lathe. This chip just didn’t want to break.

.

.

.

The light at the end of the tunnel!.

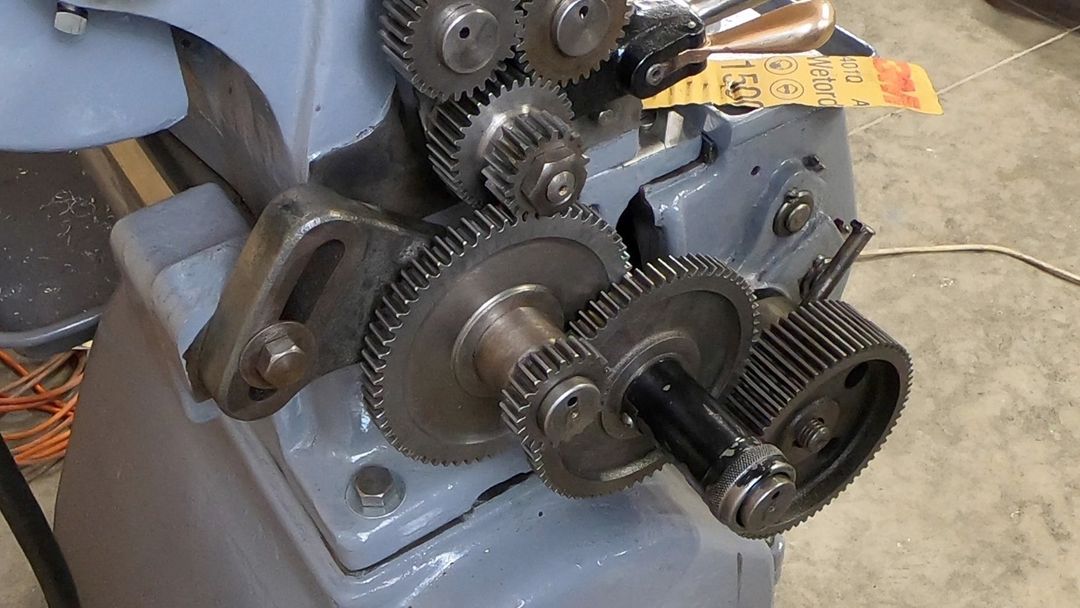

The light at the end of the tunnel! I have the primary gear train reinstalled and working. The power feeds are running as expected. I still have some fine tuning to do before I decide to run any real projects through the lathe, but I’m at the point where I can make some chips! Check my bio for a link to a video.

.

.

.

.

.

.

.

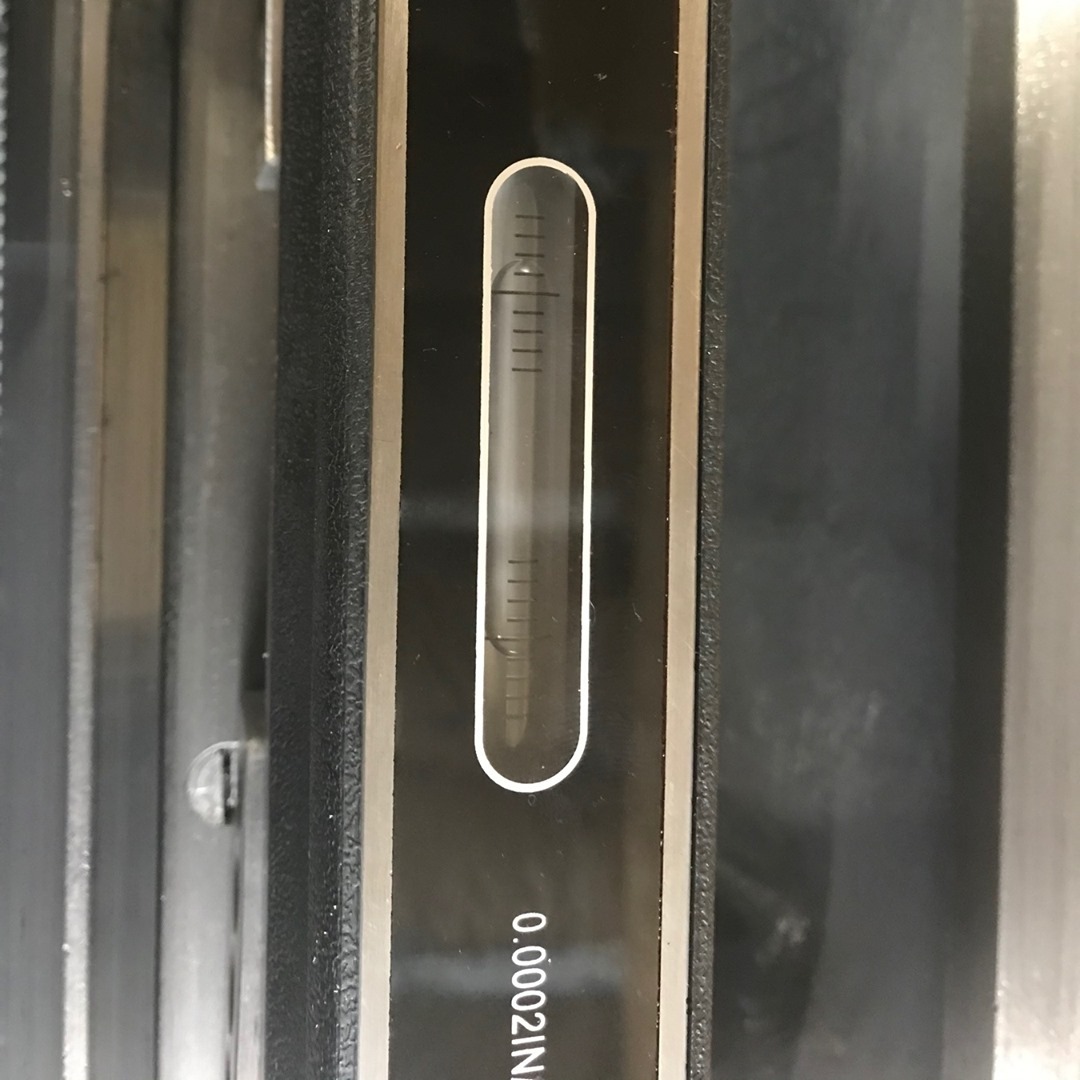

Now that the lathe is together, I am going to try and set an initial leveling.

Now that the lathe is together, I am going to try and set an initial leveling. It doesn’t have to be perfect, but I would like to take as much of the twist out of the bed as possible. This level is sensitive to .0002″ per 10″, per division line. The tiniest of adjusting on the feet can have a big effect.

.

.

.

.

.

.

.

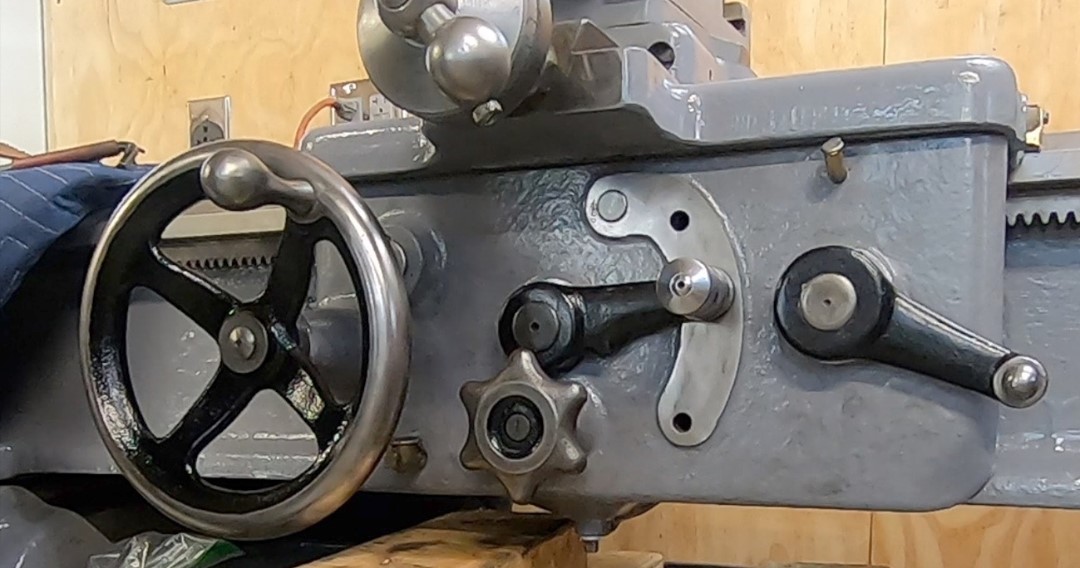

I got the apron reassembled and back on the lathe.

I got the apron reassembled and back on the lathe, although a little out of order. I was waiting until the video was ready. It’s ready! ;)

.

.

.

.

.

.

.

Do you think these half nuts are junk?

Do you think these half nuts are junk? Compared to the new one, should I replace them or just SEND IT!

.

.

.

.

Looking back at photos on how bad the apron was on the 13″ South Bend lathe.

Looking back at photos on how bad the apron was on the 13″ South Bend lathe. This thing has a lot of moving parts in it that needed to be cleaned. So glad that it’s coming together now. Almost there…

.

.

.

.

.

.

.

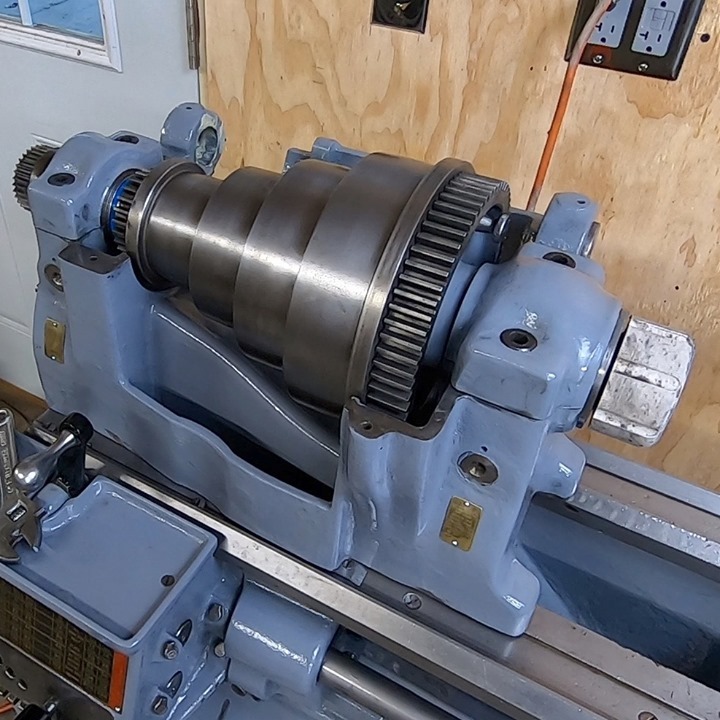

More progress being made on the restoration of my 13″ South Bend lathe.

More progress being made on the restoration of my 13″ South Bend lathe. I get the headstock back together and mounted on the bed. I do find out, however, that the forward spindle bearing is out of tolerance. I will need to address that soon.

.

.

.

.

.

.

.

Spent some time getting the pile of parts that make up the Quick Change Gearbox

Spent some time getting the pile of parts that make up the Quick Change Gearbox on my 1941 South Bend lathe put back together and installed on the machine. It went back together way easier than it did coming apart!

.

.

.

.

.

.

.