I recently bought a Bridgeport vertical mill that is in need of some work and repairs. The milling head was not attached to the base. I wanted to get it put back on, but it weighs over 100 pounds (without the motor) and the bolts are tricky to line up. I have seen other videos from Mr. Pete and H&W Machine where they used a special tool to make removing and installing the head much easier. I decided to make my own version of the tool.

•

•

•

•

•

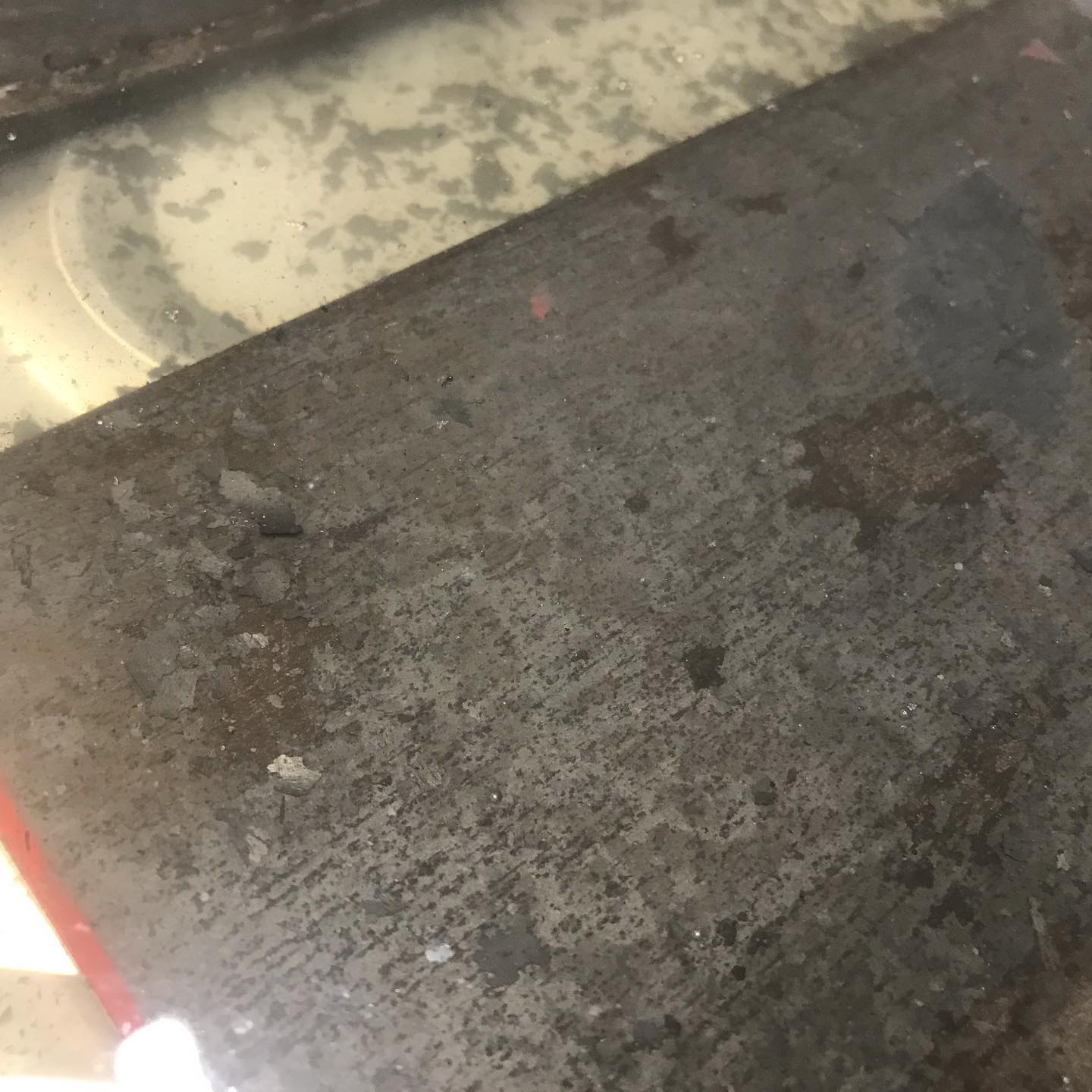

I tried giving the white vinegar soak another try.

I tried giving the white vinegar soak another try and see how effective it is for removing mill scale. Wow. It didn’t work this well last time I did. I’m a believer.

.

.

.

.

Welding god or God welder?

I used some @bluedemonweld Aluminum Bronze TIG rod to repair the worn splines on this shaft

I used some @bluedemonweld Aluminum Bronze TIG rod to repair the worn splines on this shaft from the power feed clutch on an 80 year old lathe. I have never done something like this before, and I think it went well and came out OK. Check the link my bio for a video.

•

•

•

•

•

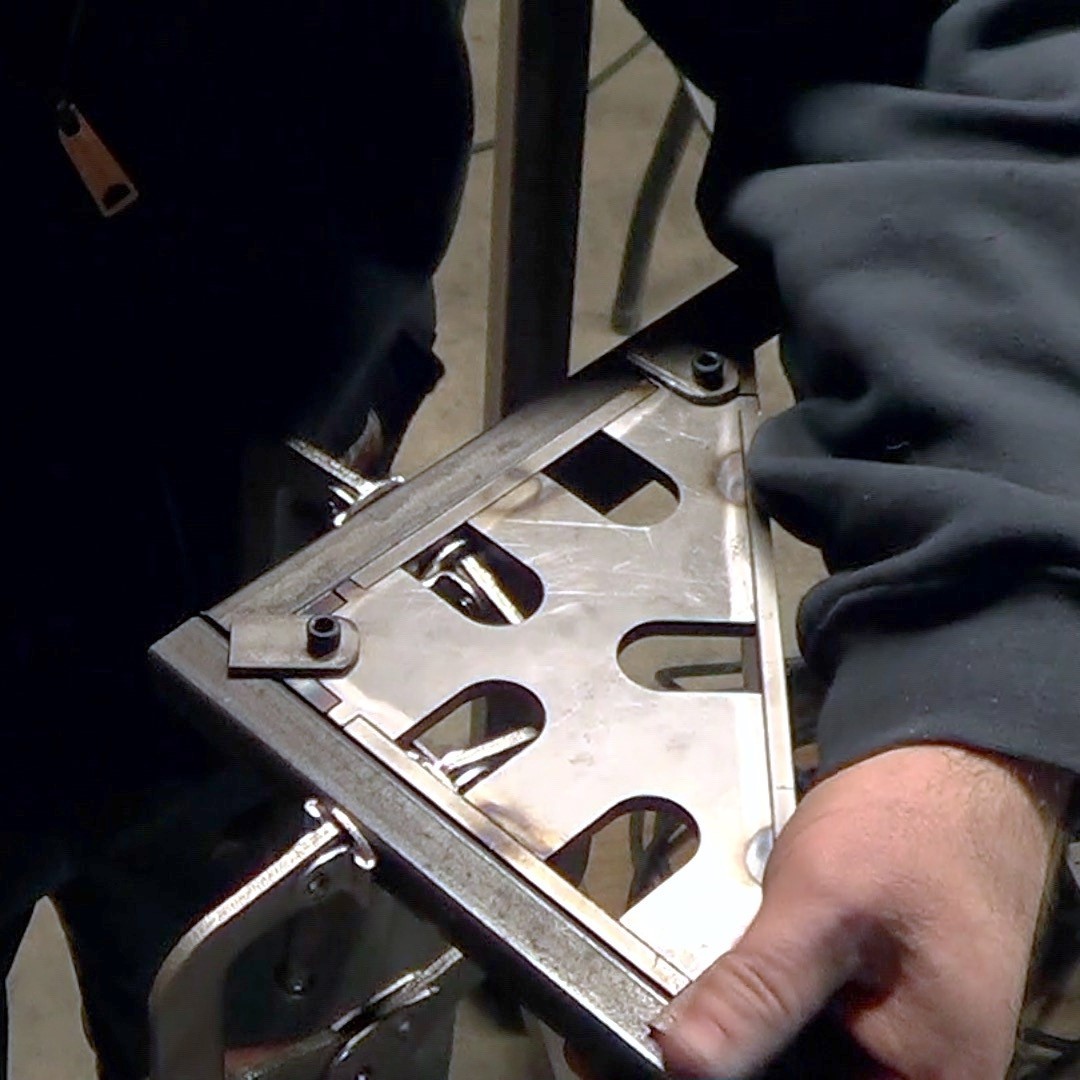

I made a second version of a welding square.

I made a second version of a welding square. These were drawn up in Fusion 360, exported as DXF files, and then sent to a CNC water jet controller and cut from .250 steel.

•

•

•

•

•

Welding squares

Inspired by a product I have seen online and used in other YouTube videos, I set out to make my own welding square. I learned a little Fusion 360 and designed this small 8″ welding square. I was fortunate enough to have this cut out on a water jet at a local maker space. Used the Primeweld TIG 225x to weld it up.

Don’t tell the cops!

Don’t tell the cops! ;)

I was making some tack welds on a project the other day and it was awkward to reach some of the areas with the torch and reach the foot pedal at the same time. I installed the finger trigger on my TIG torch to make these operations easier. I made a video of the results and some explanation of what how some of the controls on the welding machine are affected.

•

•

•

•

•

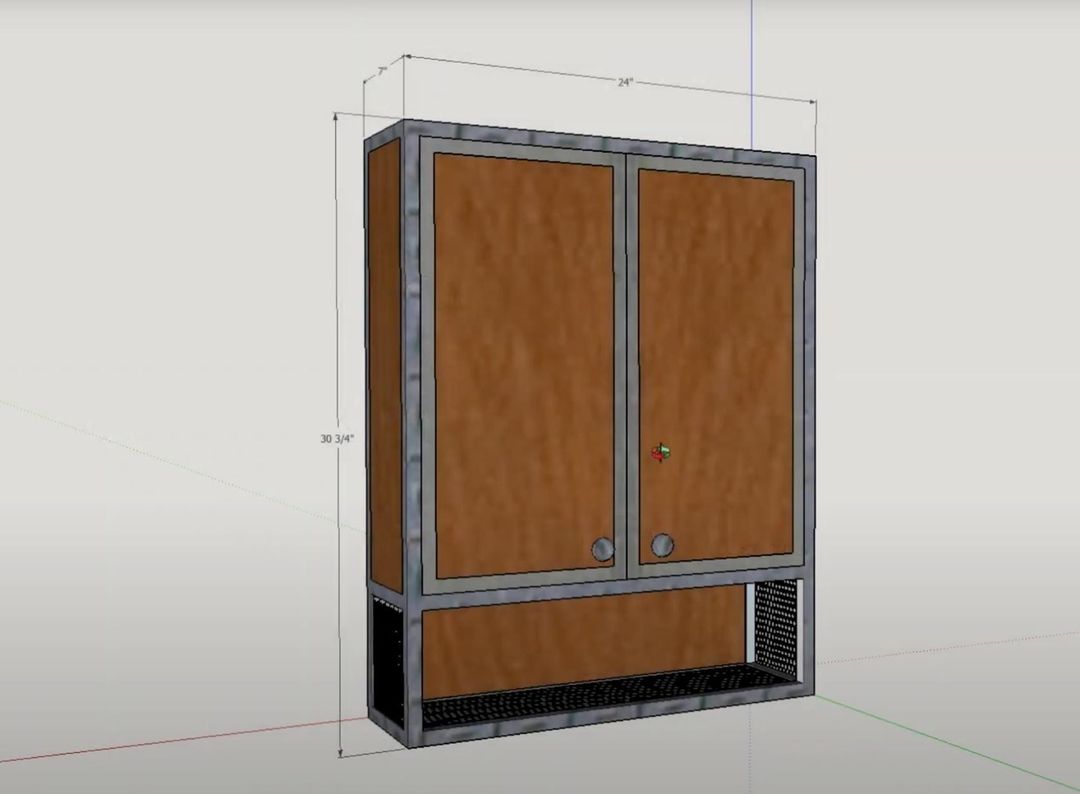

I had designed this small cabinet a while ago.

I had designed this small cabinet a while ago. When I find time, I try and make progress on it. I have the main frame finished, not it’s time to add some doors.

I saved hundreds of dollars by using my Primeweld TIG 225

I saved hundreds of dollars by using my @primeweld TIG 225 to make these locking clamps for my @weldtables welding table.