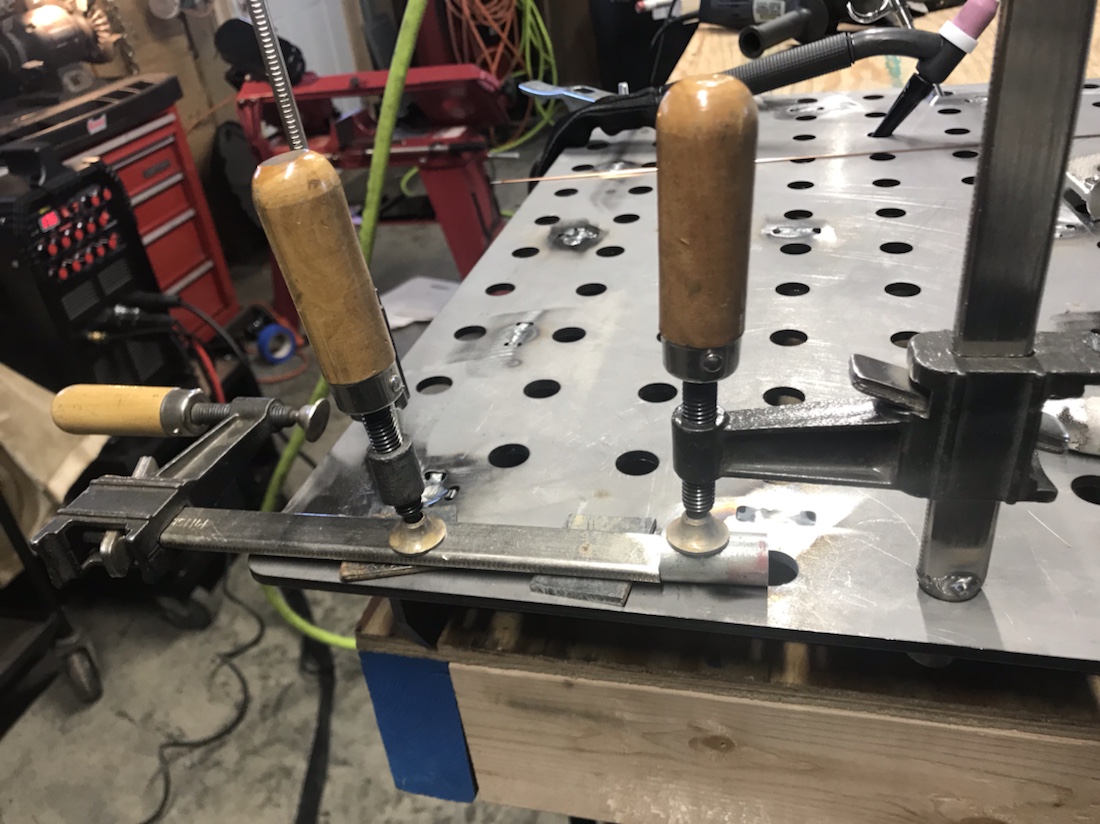

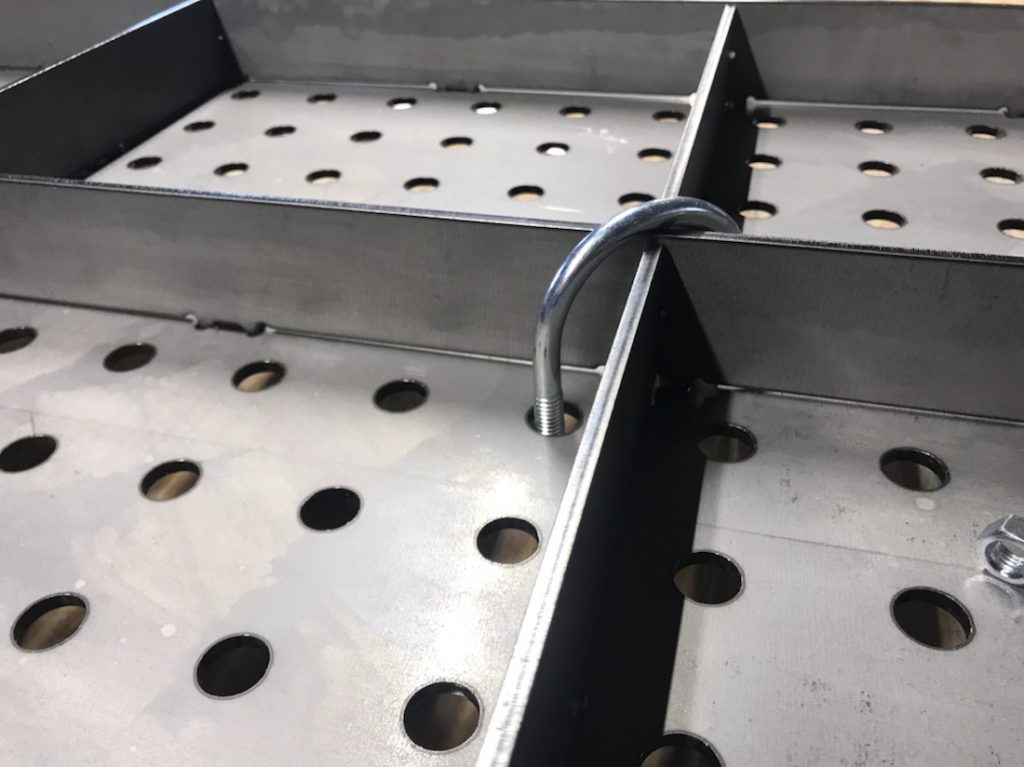

Made some hold down clamps out of some 5/8” round bar and a few old HF clamps. .

.

.

Welding table clamps

Continuing the Weekend Welding theme, I decided to make some hold down clamps for the new welding table from weldtables.com. I could buy a bunch of these for $45 a piece from Bessey, but that was just a non starter. I have seen many DIY versions of the same thing, so I decided to make my own.

I put the new band saw to use and cut some 5/8″ metal rod into a few 1 1/4″ pieces. I had a few clamps from Harbor Freight that I have had for years. You can find this for between $3 and $5 a piece depending on if they are on sale or not. I cut the end of the clamp off and then ground the rod the other end slides on to a slight angle.

From there, I welded on the small piece of steel rod.

Did this a couple more times, and vioala! I see no point in spending $150 on clamps when I can make them for $5.00 total.

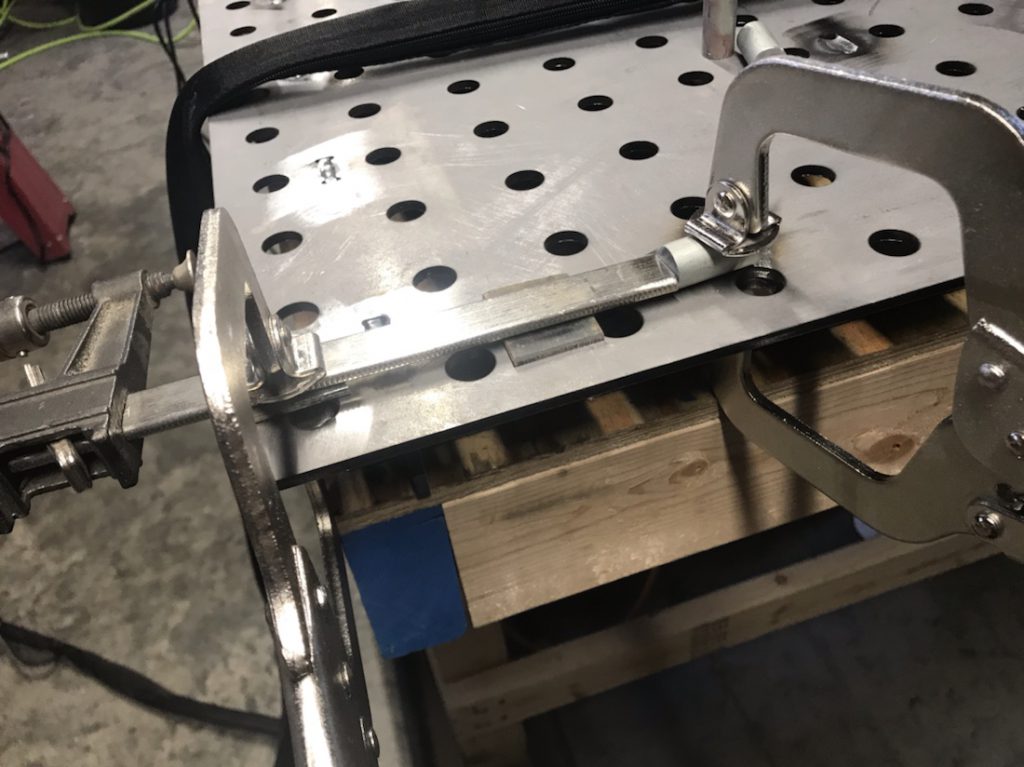

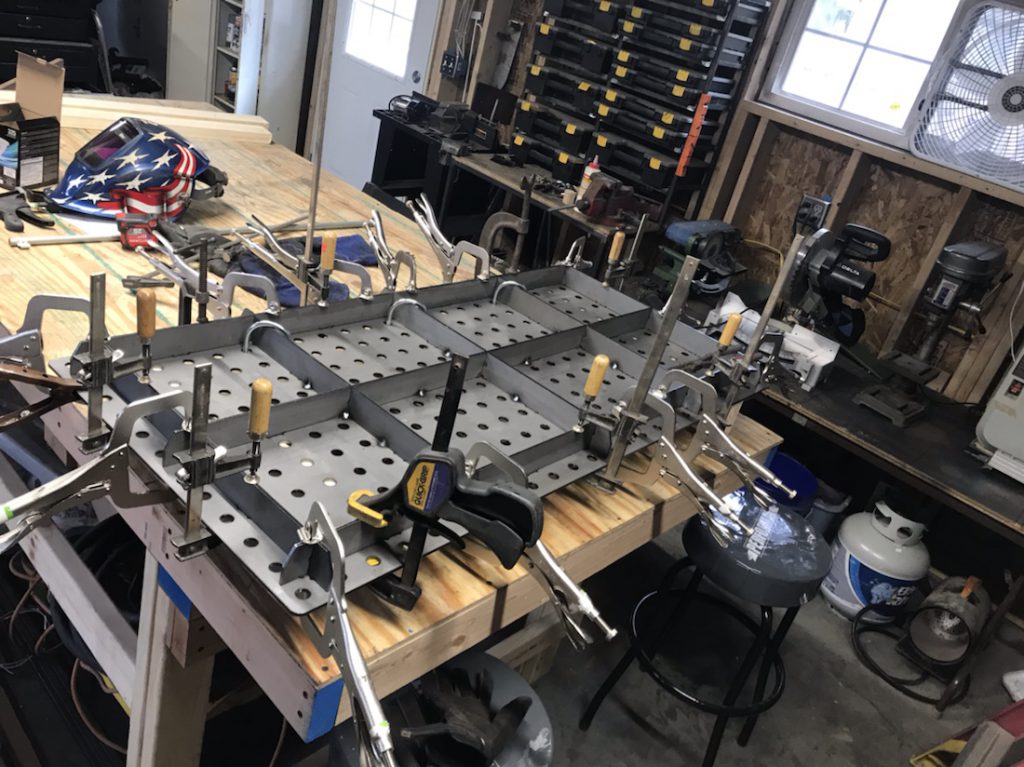

The welding table top is all welded together.

The welding table top is all welded together. Took my time making sure everything was clamped down and flat. You can never have too many clamps. 😉

.

.

.

New welding table (almost)

I have been wanting a welding table from Certiflat for YEARS. I can’t remember just where I first saw them. I finally had the space and the budget to get one this year.

It comes in pieces. A flat top, laser drilled with 5/8″ holes every 2″. There are also slots cut into the top where the tabs on the support ribs fit into.

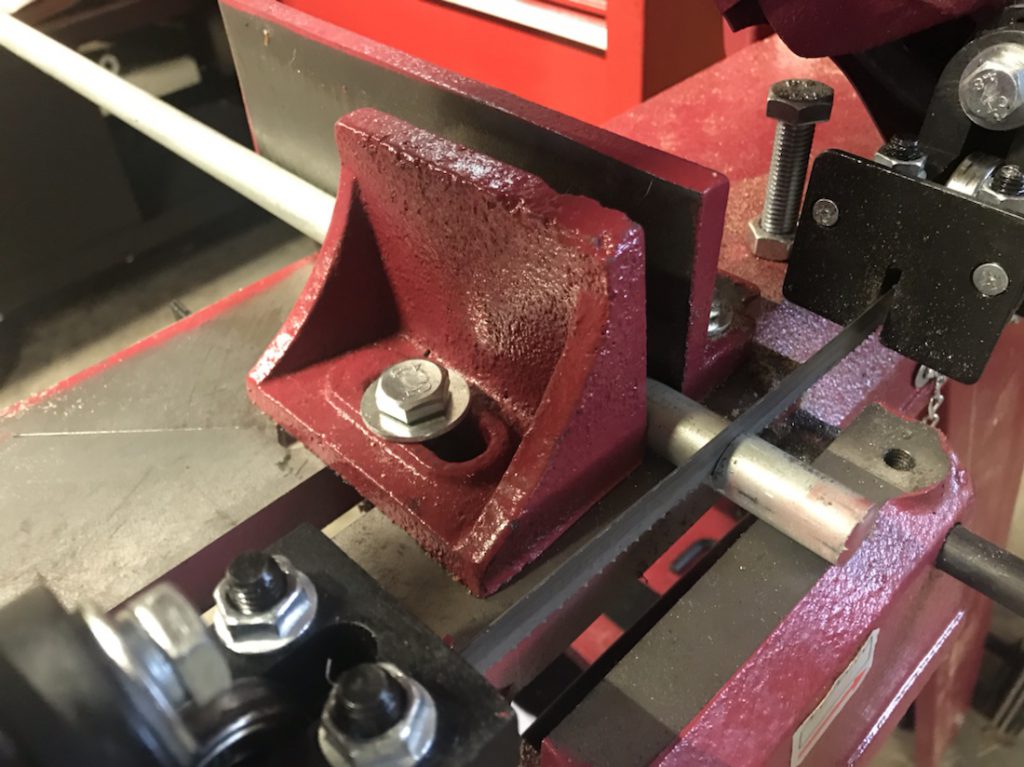

You start the build upside down, clamping the ribs to the top piece. You have to clamp it down completely to ensure the top comes out flat.

I used u-bolts to clamp down the center pieces.

I used the MIG to tack weld the center parts of the ribs together and to the table top. and then added more clamps to the outsides of the ribs.

A lot of clamps. You can never have too many. I used a flashlight to make sure there was no space between the ribs and the top, shining it on the side opposite to where I was standing, making sure I saw no slivers of light come under neath the rid.

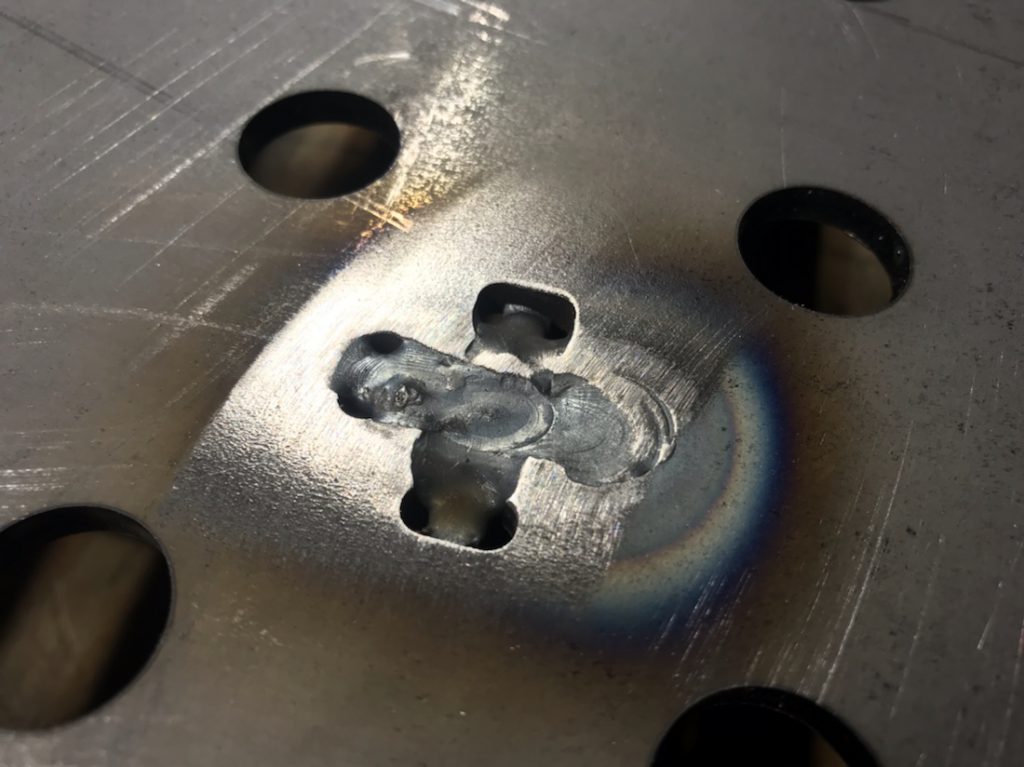

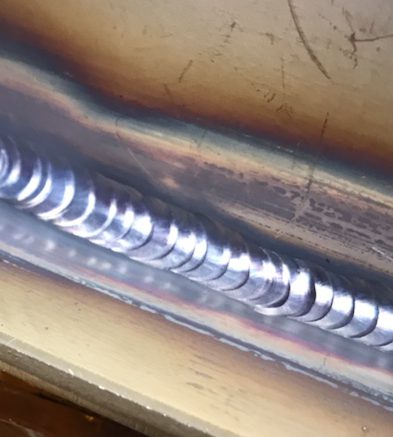

Once it was completely tacked together, I turned it over and used the TIG welder to complete the welds of the tabs and slots.

My TIG welding still needs practice, but that’s part of what this table is for. I’m debating on if I will finish welding the ribs below. I don’t think it really needs it.

The legs I ordered with this table haven’t been shipped yet. Once those are in, I’ll be able to complete this project.

UPDATE: Leg kit arrived.

I have been wanting one of these for years!

I have been wanting one of these for years! Can’t wait to build it and start putting it to use. .

.

.

Starting to get more done to the shop again.

Starting to get more done to the shop again. Ran a couple 220v circuits for each of the welders plus a 110v circuit for some much needed outlets. Changed my plans a bit and swapped the welders to the east wall so the runs are shorter.

.

.

.

Height does matter

I built this temporary work bench on top of a 6’ folding table. I plan on starting from scratch at some point and adding drawers and other storage. Perhaps some integral tools as well.

This morning I raised the surface to be 40” off the ground. What a difference! I was actually surprised by how much better it felt to lean on it and use it. Plus, my shop stool fits underneath it.

Why the modification? Well, I plan to purchase a small 2’x4’ welding table from Weldtables and the kit comes with legs that put it at a 40” height. I wanted everything to be at the same level so I can use anything as a support or out feed table.

Decided to raise the workbench up to a total of 40”

Decided to raise the workbench up to a total of 40”. Seemed like it was going to be tall, but I really like it. It’ll match up well with the soon to be ordered @weldtables welding table.

.

.

.

GTAW

I had the opportunity to attend a course at Lincoln Electric’s Welding Technology & Training Center on GTAW, or TIG welding. I recently purchased a TIG welder, and although I had a good idea of how to use it, you get so much more from hands on instruction from someone qualified to teach.

The facility itself is impressive enough. The classrooms were very clean, integrated technology well and were stocked with snacks, water and soda. Our instructors, Lance and Karl really knew their stuff. Not only did we learn a lot about GTAW (Gas Tungsten Arc Welding), but they taught us a lot about the metallurgy involved.

I also picked up some new books on welding that I will be able to refer to from time t time as reference material. “Metals and How to Weld Them” was written in the 50s and 60s and is still very relevant today.

I’m looking forward to getting some scrap steel and aluminum and practicing more and more.

3003 Aluminum / 4043 Filler

Stainless Steel / 308 Filler

A36 Steel / Silicon Bronze

Completed a week long class in TIG (GTAW) at Lincoln Electric Welding School.

Completed a week long class in TIG (GTAW) at Lincoln Electric Welding School. Hats off to our instructors, Lance and Karl. They’re tops! I appreciated the attention you can only get one on one. Unexpectedly, we also learned a lot about metallurgy. Nice bonus! Lots of time under the hood. Still need lots of practice. Hoping to score some scrap metal from some local scrap yards and still need to get a lot more filler rod. Might have to find some more classes to take!

.

.

.

.