Getting the trench dug for the workshop power. 6″ wide by 36″ deep. This thing is a beast. Read my blog post (link in bio) for more!

.

.

.

.

.

.

Someone gave me this old 3HP, 220v air compressor that needed some work.

Someone gave me this old 3HP, 220v air compressor that needed some work. The tank appears to be about a 30-35 gallon. It shouldn’t take much to get it up and running like new. See the link in my bio for the first part of the rebuild.

.

.

.

.

.

.

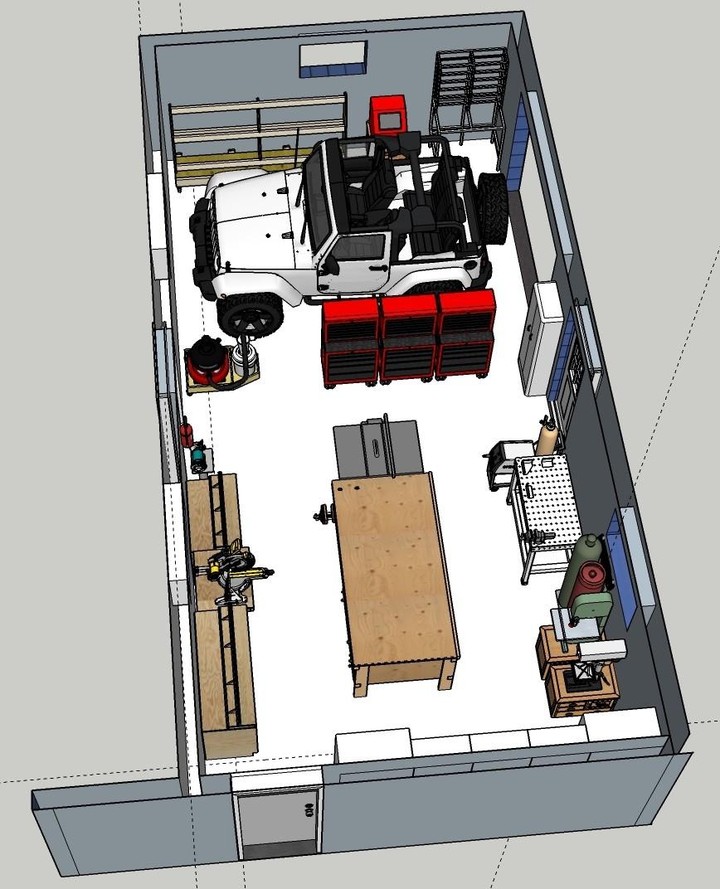

Spent some time in SketchUp trying to figure out a workshop layout.

Spent some time in SketchUp trying to figure out a workshop layout. It’s amazing how small this space becomes when you start filling it full of stuff. This will also help me figure out where I need outlets.

See more at my blog (link in bio).

.

.

.

.

.

.

.

.

Making lots of progress on the workshop.

Making lots of progress on the workshop. Concrete is set and cleaned and even managed to get the man doors and the overhead door installed. .

.

.

.

Almost there.

Almost there. A little more troweling and it will be time to sit back and watch it cure. Hopefully the heater will do what it needs to and keep the shop above freezing for the next couple of nights. .

.

.

.

Almost ready for concrete.

Getting a rocky start to the day.

Framing a small workshop in 30 seconds.

I think I could have lowered the wire feed speed just a little here

I think I could have lowered the wire feed speed just a little here, or maybe moved a little faster. Practice, practice, practice.

•

•

•

•

•

Put these Artec lower control arm skids on a friends Jeep.

Put these Artec lower control arm skids on a friends Jeep. It’s amazing how good my welds look in bad lighting and black paint. 😂

.

.

.

.

.

.

.

.